Process Improvement

Context

Keeping the variability of an industrial process under control is one of the most important objectives in manufacturing. Based on expert knowledge or on detailed functional analysis the product and process parameters that are critical to quality are identified and selected for close follow-up.

The most common and effective way for such follow-up is the Statistical Process Control which is done by using control charts but real life applications continue to be difficult to implement.

A good mixture of pragmatism and rigor is required to come up with a tool that can be easy to develop and maintain, is able to consume data in a continuous manner and provides realistic advice to effectively control production.

Selected Techniques

- Pareto Analysis

- Statistical Process Control

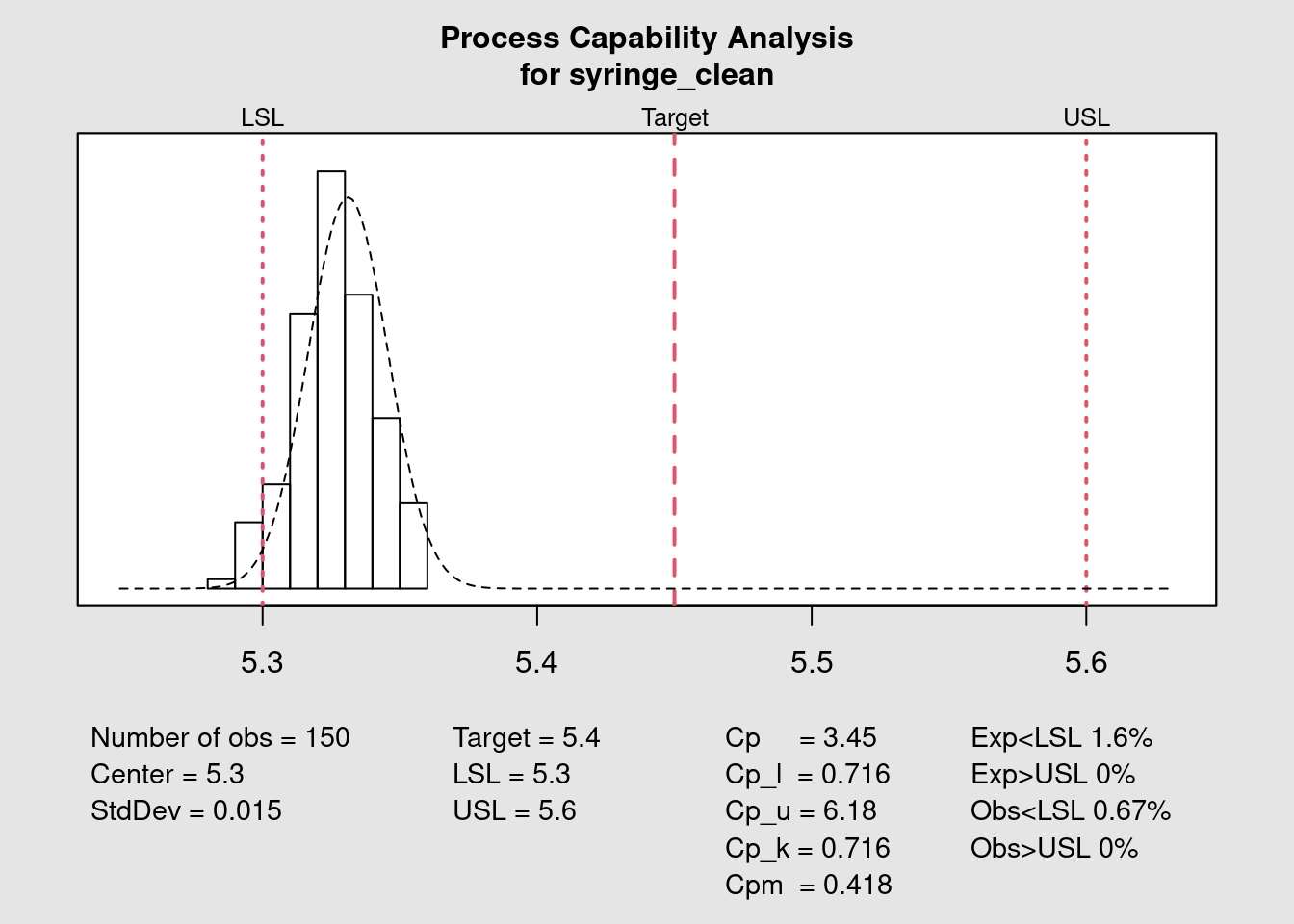

- Capability Analysis

Benefits

- Increased capacity

- Reduced waste, stoppages and costs

For advanced case studies refer to industRial SPC